A multi-million-dollar investment at the Brokenshire’s Mount Compass dairy will underpin a doubling in their milking herd size from 440 Jersey cows to 800 over the next three years.

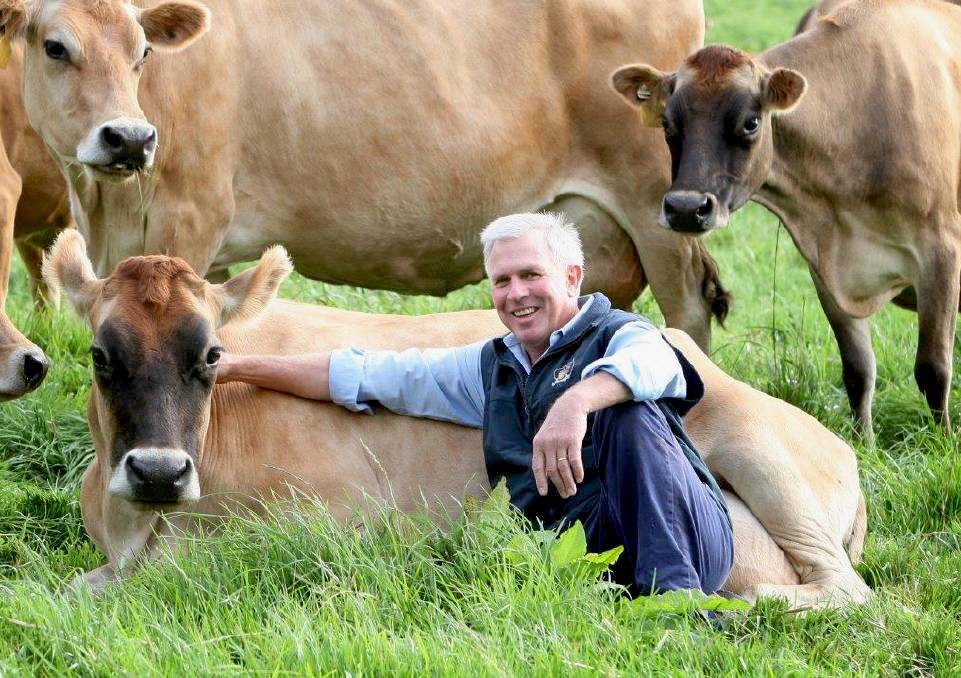

For Robert, Mandy and Nick Brokenshire, owners of Roslyn Amdena Jerseys, it’s a safe investment, given the healthy state of the South Australian dairy sector.

“The demand for milk production in South Australia is there, and we’re one of several dairy farmers that intend to grow their herds over the next few years to significantly increase the production of milk in SA,” Rob said.

The new dairy is a state-of-the-art E100 DeLaval Rotary milking system, the latest technology DeLeval offers for rotary systems.

“It’s fully computerised and once the milker cups up the cows, computers control the entire milking process,” Rob said.

“As cows are milked, milk production data for that milking will be recorded. And cow health data will also be recorded, including heat cycles and cow weight, so that if there’s a sudden drop in weight, the computer will advise us.”

The dairy will include a three-way computer controlled drafting structure so that any cow that’s identified by the computer as needing attention will be drafted off for an animal health check.

In terms of milk quality data, daily reports are sent by Fleurieu Milk, who is contracted to receive 100% of Roslyn Amdena Jerseys’ milk.

“We get reports on our phones by about the middle of each day, and they tell us the cell count – both the bacteria count and the somatic cell count,” Rob said.

“Fleurieu Milk’s demands on milk quality are high, and we’re pleased about that because it means we’re supplying the best quality milk to consumers. And we have a very focused and active food safety agency in Dairysafe, which helps us to confidently produce and sell high-quality dairy products.”

The new dairy will also be fully automated for cleaning. “It’s the best technology you can get for automatic washing and cleanliness,” Rob said.

“Cleaning will certainly be a lot easier than it used to be. Forty years ago, when I started milking, we had to cart buckets of hot water to the dairy and put the cups in the buckets to wash them.

“This fully automated system will be great for us as operators, but most importantly, it will alert us to any problems with the washing system regarding temperature, detergents and so on, so that we can address it immediately.

“With the older machines, you didn’t always realise that you have a detergent build up or a problem with your hot water temperature until you got a high bacteria count. We’ll know at every milking exactly how it’s gone, and we’ll have three different fully automated washing cycles to keep everything clean.”

The new dairy is being built on a more accessible part of the property, which will reduce the distance cows need to walk for milking.

“They don’t have to walk over a large hill anymore so that’s a good animal welfare situation for the herd,” Rob said.

“And from an environmental point of view, it has the smallest footprint, as it’s located away from any water courses. In fact, every drop of rain that falls and every bit of water used in the dairy will be captured, recycled and reused.

“Through our effluent management plan, we’ve expanded the size of our holding ponds. We now have a 28 megalitre main effluent pond. Water will continually be recycled, to wash the dairy yard and feed pad, and any additional water will be used over a large area of the farm for fertiliser spreading.”

The Brokenshire family has been running a closed herd for about 30 years, with all breeding from their own bloodlines. It will take them approximately three years to increase the herd from 440 to 800.

“Between my wife’s family and ourselves, my son is now the fourth generation on those bloodlines, so we go back four generations of breeding our Jersey cows,” Rob said.

“We’re very confident in the quality of our herd and the quality of our milk. And we’re excited about this new dairy and what it will mean for our milk production.

“I’m pleased that we’re seeing significant capital growth in the dairy industry in South Australia. Some of that is multi-million-dollar investment into robots. In our situation, it’s a multi-million-dollar investment into a state-of-the-art rotary.

“We’ve come through 10 really tough years, and this is the biggest capital works investment in modernising dairy infrastructure in South Australia that I’ve seen in 40 years.”