Between 2011 and 2020, Food Standards Australia New Zealand (FSANZ) coordinated 763 recalls, including 109 recalls in 2020. The 10-year average increased from 71 to 76 recalls per year.

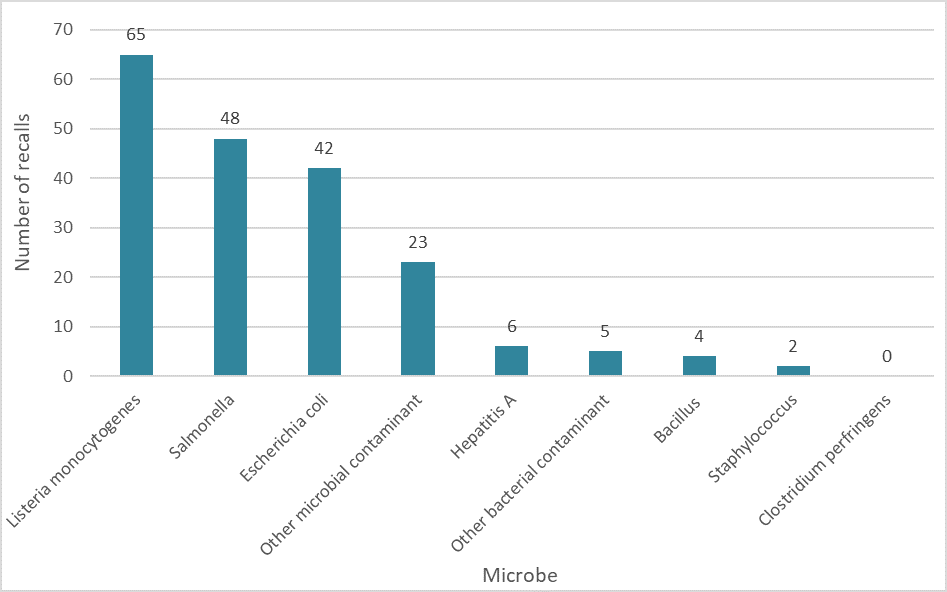

In this period, there were 195 food recalls due to microbial contamination. The most common microbes were Listeria monocytogenes (65 recalls; 33%), Salmonella (48 recalls; 25%) and E. coli (42 recalls; 22%).

Dairy products, meat products and mixed and/or processed foods were the main food groups recalled due to Listeria contamination.

Dairysafe CEO Geoff Raven said the statistics were an important reminder for the dairy industry to take action to prevent listeria.

“Listeria is the leading cause of microbial contamination recalls,” Geoff said. “Listeria infection is among the most serious food related illnesses and can be fatal.

“All members of your staff are critically important in protecting your product and business from the risk of listeria.

“Are your staff adequately trained in hygienic practices relating to their job? The best of systems and equipment does not eliminate the risk of contamination if your people do not understand how contamination can occur.

“Have you sought out other information, resources and training to ensure your staff and business are fully capable of managing listeria?”

The Dairysafe website contains a listeria webinar series specifically developed for the dairy industry which is ideally suited to new employees or as a refresher. There is an online evaluation and certificate of completion. You can find it here.

How does listeria develop?

Listeria can be introduced into the production facility by products or ingredients that that haven’t received an adequate microbial kill step. Raw milk may contain listeria and so segregation of raw and processed products is critically important to prevent possible cross-contamination.

Ingredients that are not heat-treated, or are added after pasteurisation, are potential hazards and so it’s important these are purchased from suppliers that can provide an assurance the products are free of listeria.

Additionally, handling ingredients and packaging can be potential sources of contamination, which is why every dairy processor is required to have detailed arrangements for pre-requisite programs such as hygiene, storage and cleaning (GHP and GMP).

“And finally, because listeria are widespread in the environment, people can easily bring listeria into the processing environment, so it is important to restrict the entry of personnel into high-risk production areas to assist in reducing the risk of contamination,” Geoff said.